OEM/ODM

Design to Deliver

Motor Manufacturing

Part 1

StatorPart 2

RotorPart 3

HousingPart 4

Assembly

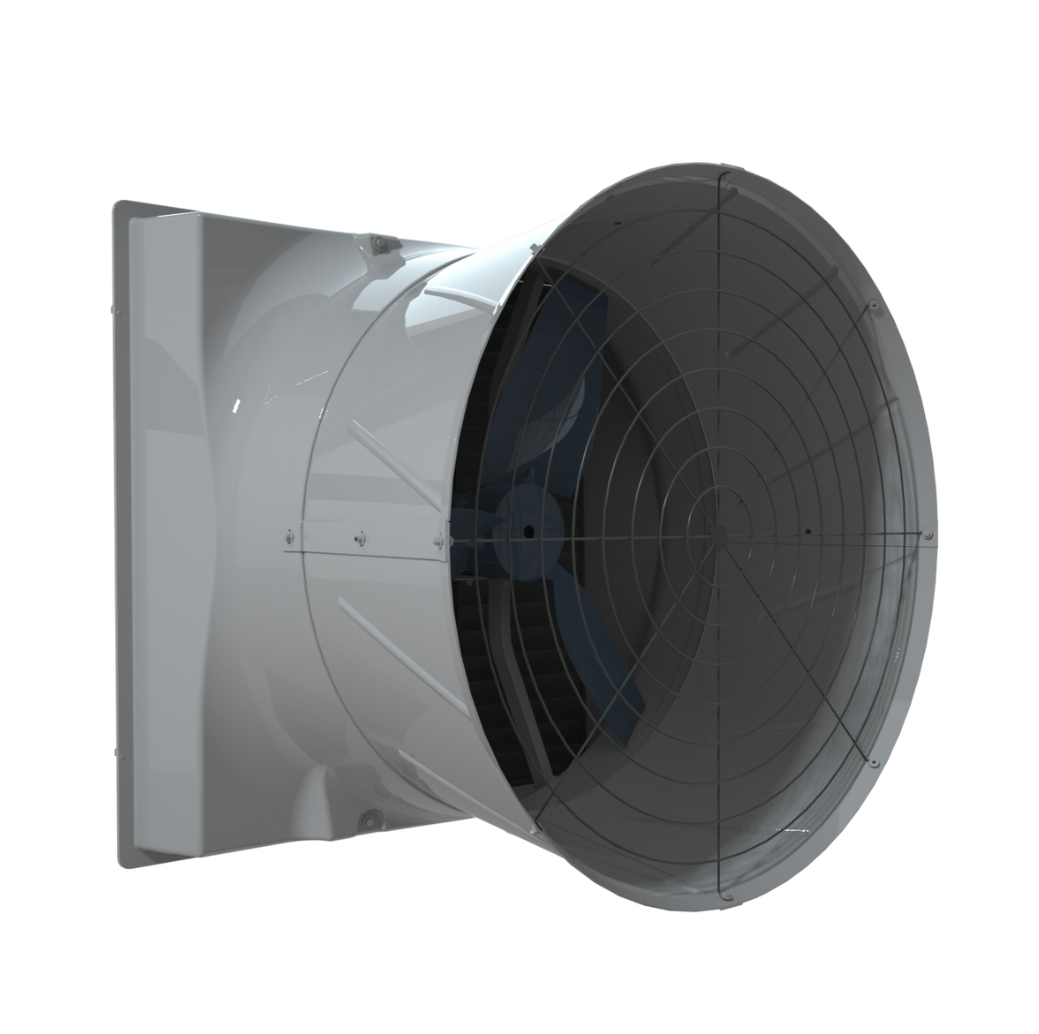

Fan Assembly

Part 1: Part QC

Part Receiving Part QC check Stock InPart 2: Impeller

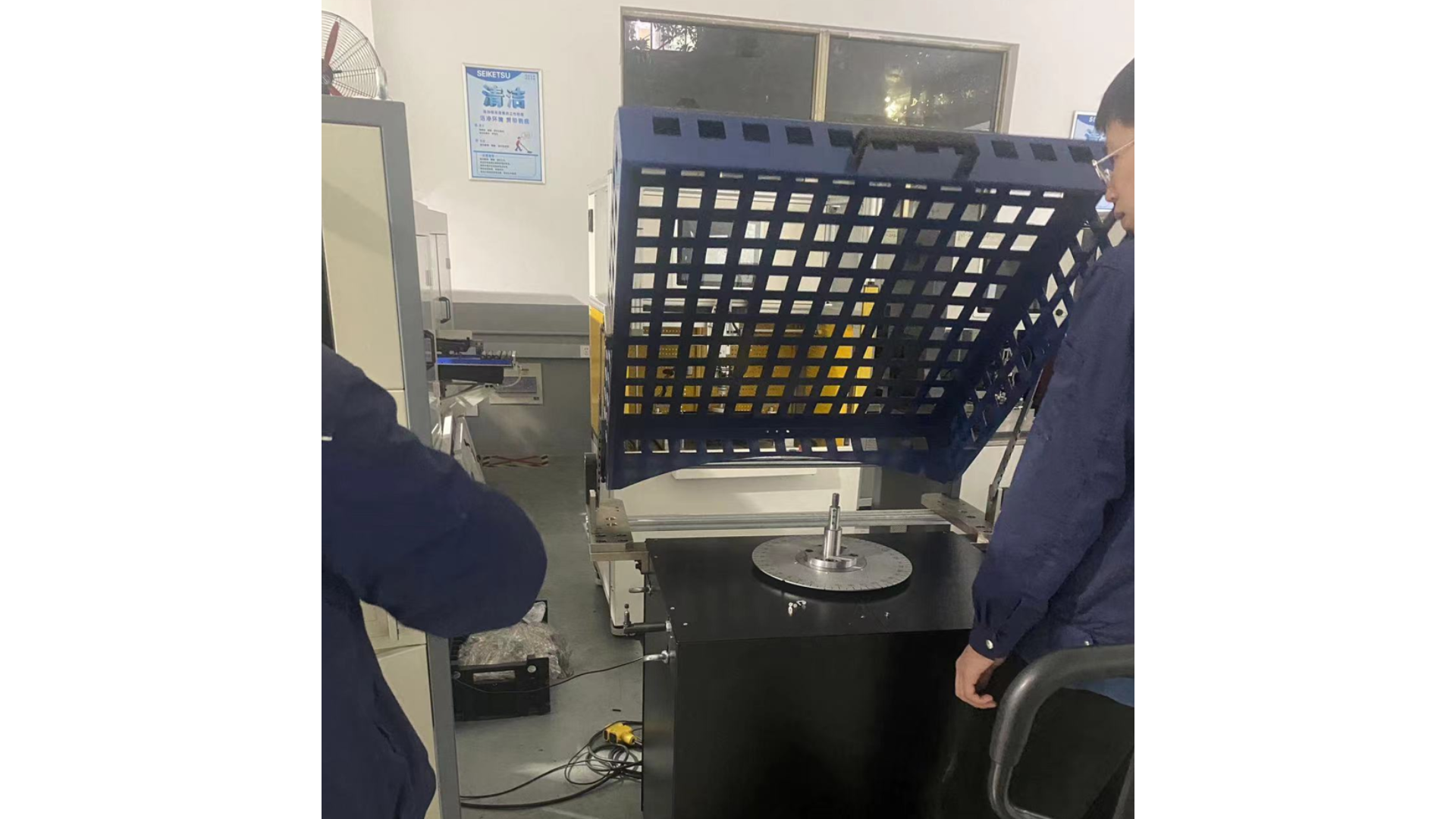

Impeller Assembly Rotary BalancingPart 3: Testing

Loaded Motor Testing Motor & Impeller packingPart 4: Assembly

Fan Assembly Fan Testing Packing

QC Assurance

Various fan housing manufacturing techniques option.

Plastic part is produced through Injection moulding mainly, vacuum moulding is optional.

Matured partnership with part manufacturer to ensure delivery quality.

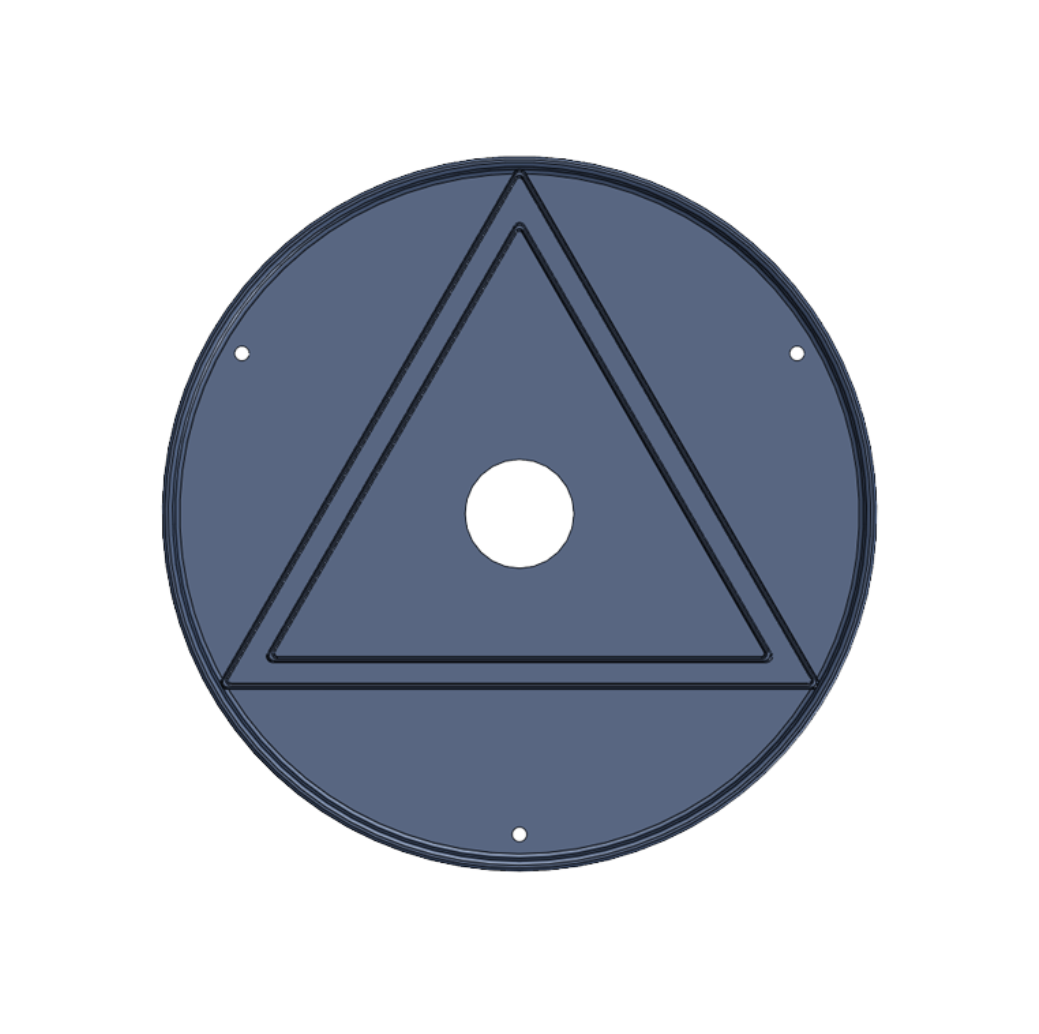

Impeller blade is main focus of fan structure where each

blade is measured and packed according to weight difference of 1g in set.

FRP part is produced via SMC process mainly, strict

selection on raw material quality to ensure good mechanical strength and lifetime.

Other composite materials are strictly selected to ensure good performance on durability and working environment.

Metal part fabrication is completed through precision metal manufacturing equipment.

We have used high quality metal material that can achieve higher lifetime against corrosion.

Each metal part is controlled strictly on the size tolerance and precision.

We have used high corrosion resistance accessories for fastening kits.

Products